Advancements in flow measurement technology

In industrial settings, accurate and reliable flow measurement is crucial for monitoring, optimizing, and protecting production processes. Properly measuring the flow of air, gas, or liquids helps prevent energy waste, boosts efficiency, and extends equipment lifespan. As energy prices climb and sustainability becomes more important, flow measurement plays a vital role in reducing operational costs and improving performance.

Flow measurement technology continues to evolve. Innovations such as advanced silicon (MEMS) thermal flow sensors, digital communication protocols like Modbus RTU, and real-time data analysis are making flow meters more precise, reliable, and user-friendly. These advancements empower companies to make smarter decisions, improving overall system reliability and efficiency.

The evolution of flow measurement

Flow measurement has a long history — even ancient civilizations recognized the importance of controlling water flows for agriculture and infrastructure. One early example is the Roman clepsydra, or water clock, which measured time using a steady flow of water. While not industrial, it marked an important step in understanding how fluid movement can be measured and controlled.

With the industrial revolution came the need for more precise tools, leading to the invention of mechanical meters like turbine and positive displacement flow meters. Today, flow measurement is a key part of industrial process optimization. In applications like compressed air and nitrogen monitoring, thermal mass flow meters are widely used. For effective monitoring, bi-directional flow meters with integrated pressure sensors are now considered essential.

Flow meters serve several critical purposes: detecting leaks early, allocating costs for compressed air or technical gases, and monitoring system efficiency — all contributing to better process management and energy savings.

Latest innovations & how they improve accuracy

One of the most significant recent developments in flow technology is the introduction of flow meters with exchangeable sensor cartridges. These address two major issues for plant and maintenance managers: downtime during recalibration and the high cost of spare flow meters.

Rather than removing the entire flow meter for recalibration — a process that’s both time-consuming and disruptive — you can now simply replace the sensor cartridge on-site. This innovation reduces the need for backup meters, shortens maintenance time, and cuts recalibration costs.

By simplifying sensor maintenance, this technology helps facilities maintain accurate readings without interrupting production. It enhances reliability, streamlines logistics, and supports ongoing process optimization — making it a smart upgrade for any modern plant.

Applications & the future of flow measurement technology

Flow meters have a wide range of applications, from basic domestic gas meters to advanced Coriolis meters used in the custody transfer of chemicals. In industrial energy management, here are a few key uses:

- Compressed Air System Monitoring

Detect leaks, optimize compressor performance, and reduce energy waste. - Cost Allocation of Compressed Air

Track usage across departments to assign costs fairly, identify savings, and prevent losses. - Industrial Gas Monitoring

Accurately measure gases like nitrogen, CO₂, argon, and oxygen in food, beverage, pharmaceutical, and chemical production.

A newer and highly effective application is the permanent monitoring of compressed air use during the design phase of pilot plants. Instead of relying on estimates to size equipment, engineers can now use real consumption data — even before the plant is fully operational.

In a recent case, continuous flow monitoring during a pilot phase revealed that the compressed air system was drastically oversized. This caused frequent on/off cycling of large compressors, leading to wear, vibration issues, and unplanned downtime. After resizing the system based on actual usage, the facility achieved double-digit energy savings and eliminated the mechanical issues.

This example shows how data-driven design can prevent costly mistakes, improve system reliability, and unlock long-term savings.

Where flow and power meet – efficiency happens

When combined with electric power measurement, flow meters become even more powerful for managing industrial energy. While flow meters track the use of compressed air and gases — often among the most expensive utilities — power meters show the energy input required to produce them.

Together, these tools offer a complete energy picture: how much energy you use, and what you get in return. This combined view allows for detailed analysis of inefficiencies, equipment benchmarking, leak detection, and true cost per production unit.

By linking flow and energy data, companies can uncover hidden losses, fine-tune systems, and make better decisions. The result? Major energy savings, reduced operational costs, and greater sustainability. Flow and power data together pave the way to maximum efficiency and smarter, greener operations.

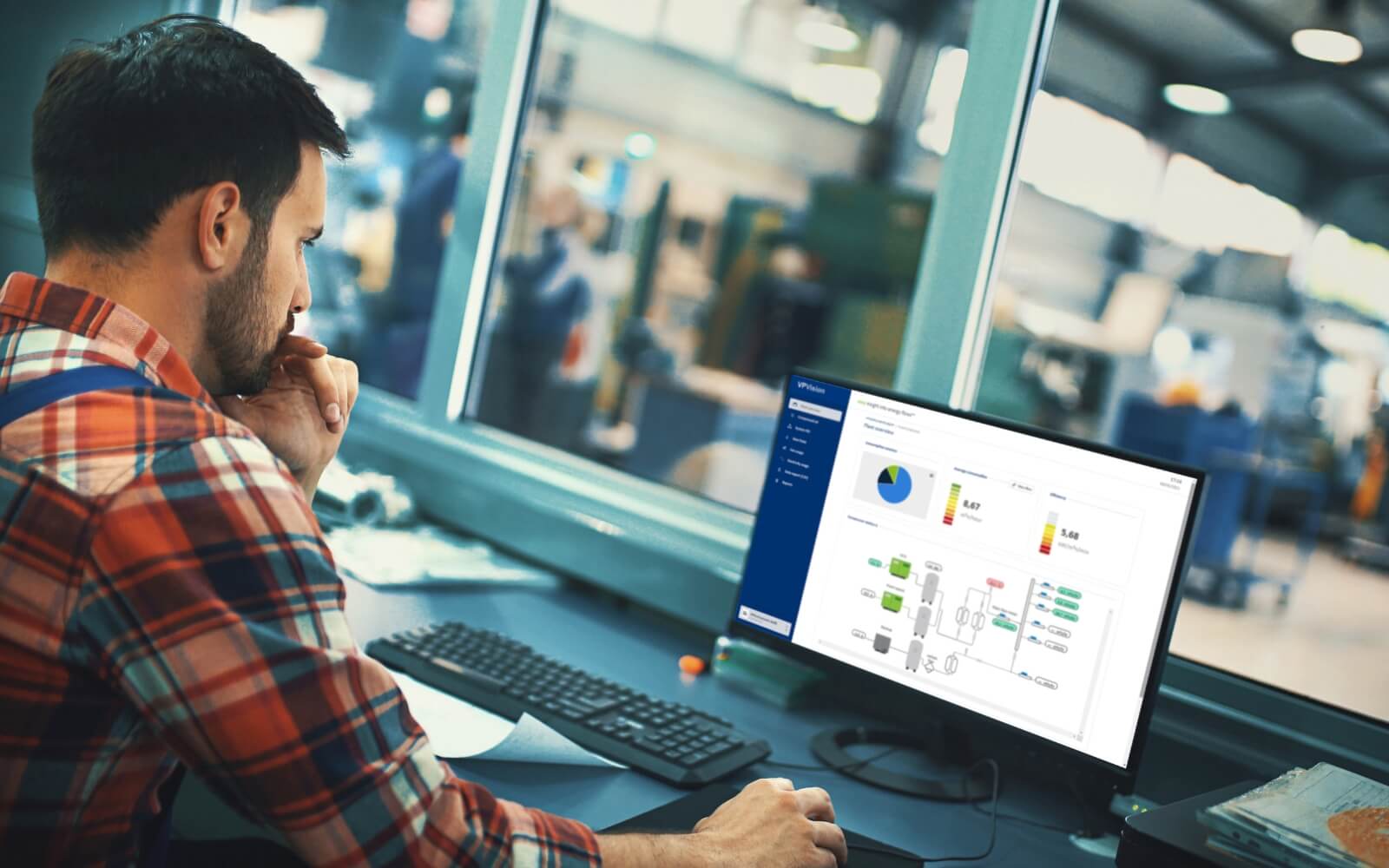

Gain direct insight into your energy flow and reduce costs with VPInstruments

Soon you’ll not just be measuring air – you’ll be walking on air too because of the results!

Get a free presentation for you and your team on the benefits of permanent monitoring

A permanent monitoring of your compressed air and other utilities is key to maximizing energy savings. It comes with many benefits as the example above shows, including data-based investment decisions, alarms, increased awareness, and in some cases even an increase in production. Our team experts provide free-of-charge an online presentation to you and your team on the benefits of permanent monitoring. Interested? Make your appointment today!