Ensure and improve production capacity using a flow meter in the food & beverage industry

The food and beverage industry is one of the most energy-intensive sectors, relying heavily on compressed air and technical gases for critical processes such as packaging, cooling, and automation. At VPInstruments, we provide tailored energy savings solutions that help food and beverage manufacturers reduce waste, optimize performance, and gain complete visibility into their energy usage. Discover how our proven technologies and expertise can support your sustainability goals while lowering operational costs.

Measure, Discover and Improve in the food and beverage industry

Your utilities, including your compressed air system, are of great importance for your production capacity. This is particularly true in energy-intensive sectors such as the food and beverage industry, where the consumption of utilities such as compressed air, nitrogen, CO2, and others is substantial. Enhancing the efficiency of these utilities directly translates into improved production. However, where should you start?

By utilizing a 4-in-1 flow meter, you can acquire valuable insights into your energy flows. Unveil major consumers, identify leakages, detect inefficient usage, and pinpoint overdue maintenance. With real-time data at your disposal, your investments in improvements can be justified and you can effectively manage maintenance, resulting in reduction of costs and conserving both money and energy. Flow meters accurately measure and display the consumption of air or gas, equipping you with vital information regarding where, when, and how much is being used.

Personal advice

Unsure how a flow meter can help you? Or would you like to receive more information about one of our products? We are happy to help!

Leave your contact details here if you want to receive tailored advice. One of our experts will get in touch with you.

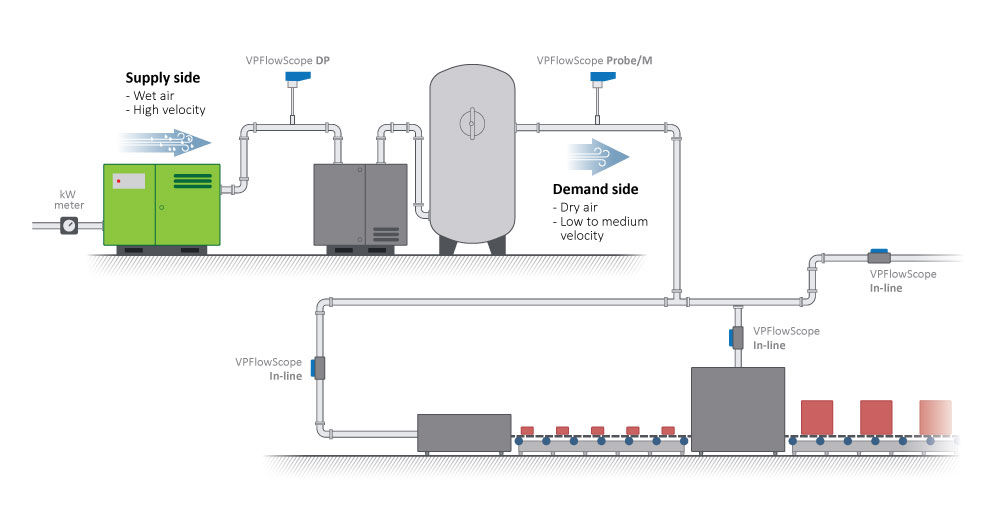

Choosing the right flow meter with easy installation

When it comes to flow meters, there are several options available, each with its own distinct characteristics. For applications involving compressed air and technical gases, the most commonly used flow meters are thermal mass and differential pressure flow meters, as well as insertion type and in-line flow meters. With this range of flow meters, you can effectively measure your entire system, from the supply side to the demand side. Whether you need to detect small leakages or assess the overall consumption profile, these flow meters offer a great balance between price and accuracy, ensuring a significant return on investment. The installation process is simple, and insertion type flow meters can even be installed under pressure, eliminating the need for production downtime. With these flow meters, you can easily achieve accurate measurements without disrupting your operations.

VPFlowScope 4-in-1 flow meters benefits

If you are looking for a reliable flow meter to measure industrial gases or compressed air, the VPFlowScope portfolio is here to meet your needs. From the supply side to the demand side, these flow meters provide reliable measurements. They are specifically designed to measure various industrial gases such as compressed air, nitrogen, CO2, oxygen, helium, argon, and more. The VPFlowScope flow meters all offer the complete picture of your system’s performance by measuring four key principles in one: mass flow, pressure, temperature, and total flow. Moreover, our flow meters support bi-directional flow measurement, making them highly suitable for applications like ring networks.

With their modular concept, the VPFlowScope flow meters allow you to start small and expand over time. Our exchangeable VPSensorCartridge system ensures easy servicing without disrupting production. The flow meters feature a user-friendly interface and seamlessly integrate with any Building Management System (BMS) or energy management system, simplifying data integration and analysis. Installation is a breeze, especially with our insertion type flow meters, which can be inserted and removed without stopping production by using a ball valve.

✓ Four-in-one sensor

✓ Bi-directional flow measurement

✓ Modular design

✓ Easy-to-install and use

Applications

- Demand side and supply side compressed air monitoring

- Industrial gas monitoring: air, nitrogen, carbon dioxide, argon and other dry, noncorrosive industrial gases

- Air audits

- Submetering and cost allocation

- Leak detection

- Maintenance management

- Monitor and optimize the control system

- Sizing of equipment

- Compressor efficiency monitoring

Quick support and service for the food and beverage industry

VPInstruments’ flow meters are known for their Dutch quality and high reliability. We provide a wide range of local partners who can assist you on-site with your measurement project or turnkey installation. In the rare event that something goes wrong, we offer fast and dedicated support through our in-house support engineers. With our exchange service and the exchangeable VPSensorCartridge principle, replacing a flow meter is a quick and effortless process, taking just a matter of minutes.

Discover your savings potential

With just a few parameters, you can already get a rough idea of the annual costs for the compressed air consumption. There are different ways compressed air is wasted. A common one is leakages which every compressed air systems has. This is your low hanging fruit. Measure them, allocate them and start saving money!

A few examples where VPInstruments’ equipment led to improvements

Would you like to receive more information about our Flow Meters?

"*" indicates required fields

We try to follow up all requests within 24 hrs during work days.